Vacuum Ovens

Vacuum Oven - Cubic and Cylindrical Chamber Shapes - Max. Temperature 200 ˚C

THERMANSYS OVN-VAC-200 Vacuum Ovens are available in both cubic chamber shape for larger useful surface and cylindrical chamber shape for optimum temperature uniformity.

The inner chamber made of corrosion-free stainless steel ASTM 304, resistant to most acid, is designed to maintain Vacuum conditions up to 10-2 torr (mmHg). Heated by stainless steel heating jackets all around the chamber supports homogenous temperature distribution through interior of the chamber.

With a door having a large double wall transparent window provides full visual inspection of the treated samples. The internal window is made of safety glass that is spring mounted to act as a safety valve in case of overpressure event. The outer window is made of polycarbonate transparent material as a double safety measure. The door vacuum seal is provided by an endless high temperature Silicone gasket.

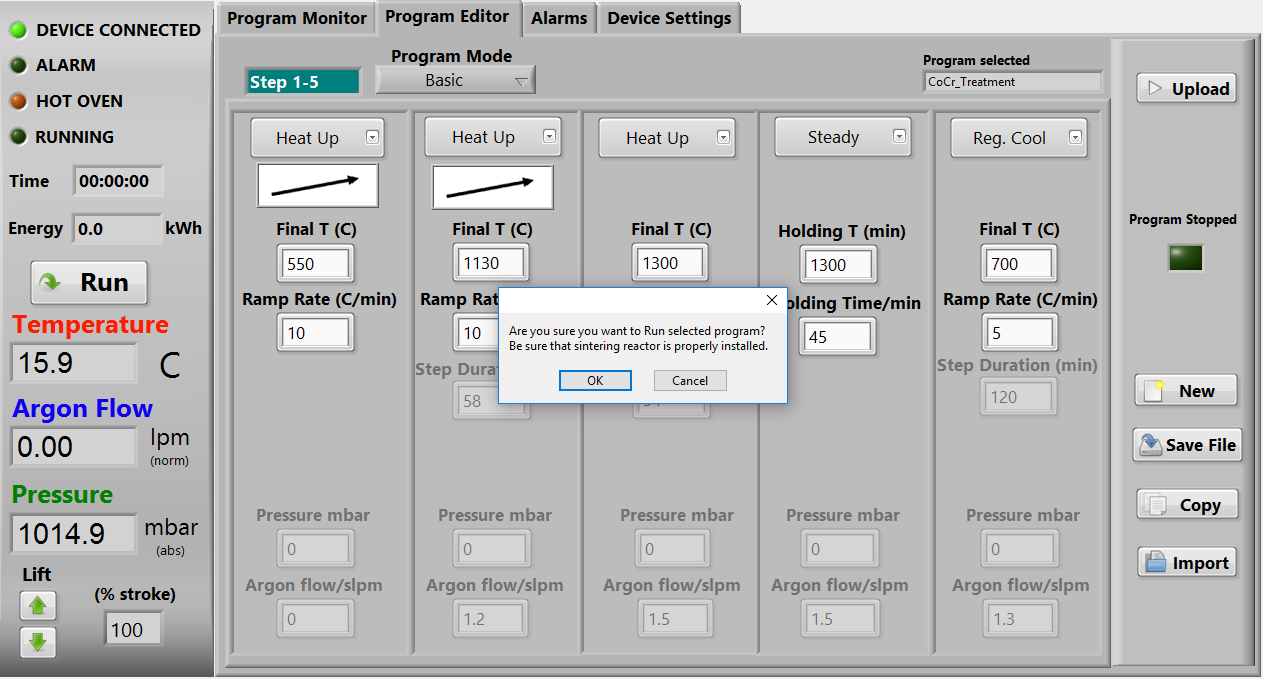

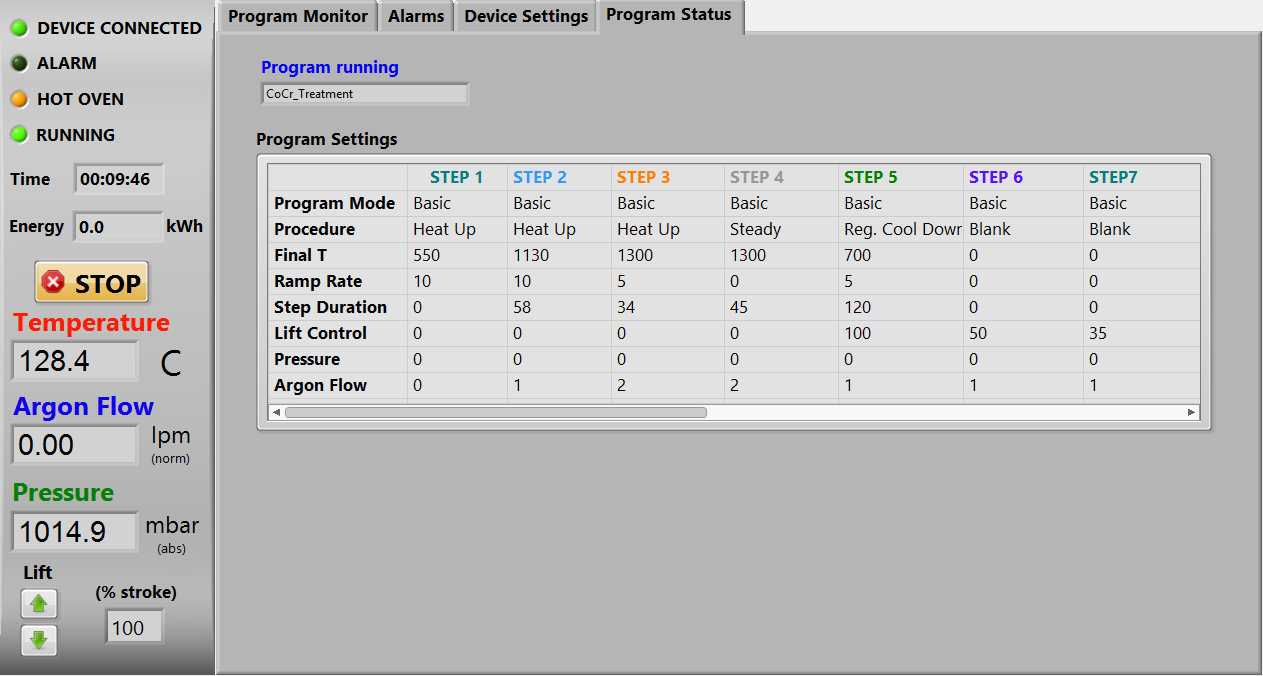

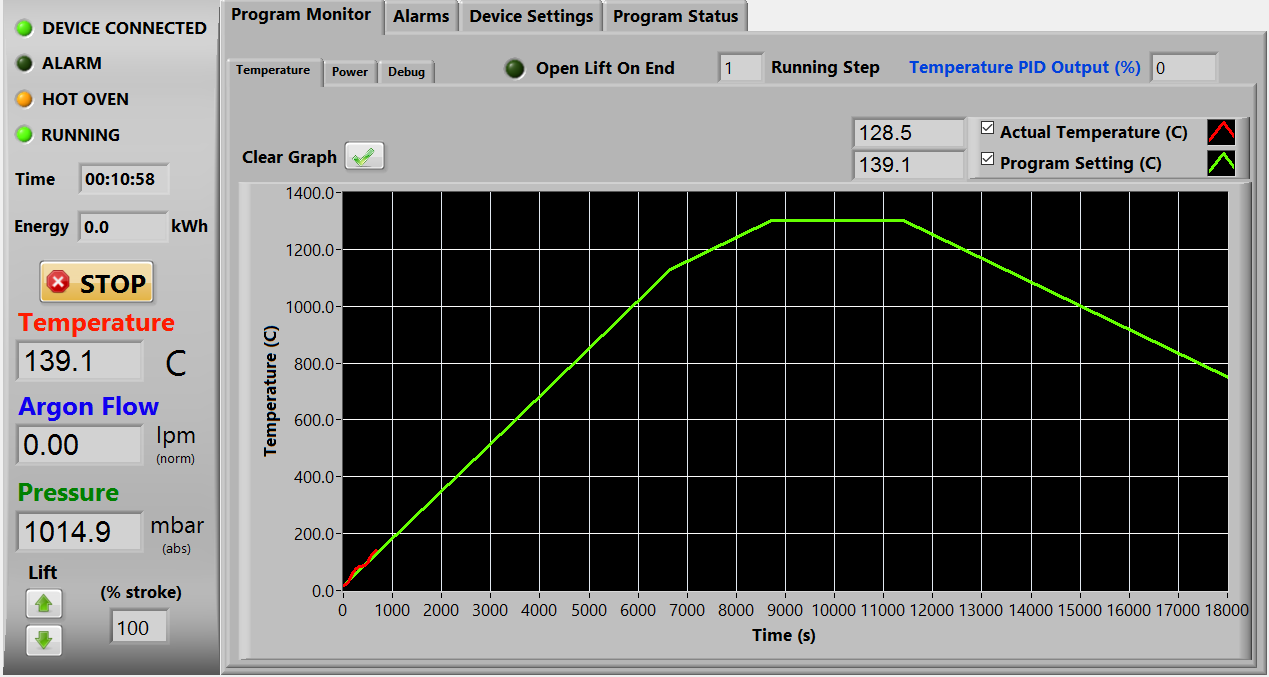

Temperature, Pressure and Vacuum Pump are controlled and monitored digitally through PYROLOGISM software. Connecting an inert gas supply the software can provide upstream pressure control.

Suitable for many applications including Electronics/Semiconductors, Pharmaceuticals/Cosmetics, Plastics, Agricultural and other. Not suitable for flammable solvents drying.

Key Features

- Control strategy by Thermansys PCC (Power Consistent Control) insures silent operation and compliance with EMC standards.

- Temperature and Pressure PID control, accurate and uniform temperature profiles.

- Temperature and Pressure data digital monitoring and storage.

- Equipped with Aluminum sliding shelves enhance the fast and uniform heat transfer to the samples. Each shelve, as also the entire shelves mounting block, is fully removable for easy cleaning and disinfection.

- Power and true RMS Current measuring circuits.

- 7.0΄΄ touch screen computer running the user friendly, PYROLOGISM software.

- Heater failure, open control thermocouple detection alarms and interlocks.

- Stand alone over-temperature limiter (Watchdog) with manual reset in accordance with EN 60519-2 to protect the heater and load. Alarm event output (dry contact 3A/250V AC/DC).

Specifications

- Temperature control range, 5 ˚C above ambient to 200 ˚C. Monitoring resolution 0.1˚C.

- Operating Power: 208 /240VAC – 50/60Hz. Rated maximum Power 2300 W (For Heater and Pump)

- Two in depended Pt100 type embedded temperature sensors for controller and over-temperature limiter feedback.

- Temperature control setting resolution 0.1 ˚C. Typical control fluctuation ±0.1˚C

- Permitted end vacuum 10-2 torr (mmHg). Permitted maximum pressure 780 torr (mmHg) absolute.

- Vacuum Pump connection port, Klamp Flange KF DN25, Inert gas inlet connection, ¼’ Compression fitting

- Optional instrumentation port,Klamp Flange KF DN25

- Main door seal: Red Silicone gasket, continuous operation temperature 250 ˚C.

- Pressure transducer range 0.3-776 torr (mmHg), calibration accuracy ±1% full scale, response time 2msec

- Optional Pump supplied with the Oven: Oil Rotary Vane, double stage, 2-5x10-2 torr end vacuum, free air displacement 118lpm (170 lpm for 67 heated volume model).

CE Certified. Compliant with Low Voltage Directive 2006/95/EC (harmonized referenced standard EN 61010-1: 2001 and EN 61010-2-010:2003) and EMC Directive 2004/108/EC (harmonized referenced standard EN 61326-1:2006).

Produced in GREECE following ISO 9001:2008 quality management system and ISO 14001:2004 environmental management system.

Models

Cubic Chamber - Max. Temp. 200 °C, Heated Volume 29 and 67lt

| Model No | Max. Temperature (C) | Heated Volume (lt) |

| OVN-VAC-V29-200 | 200 | 29 |

| OVN-VAC-V29-200 | 200 | 29 |

Doc No. OVN-VAC-200 February 2015

Cylindrical Chamber - Max. Temp. 200 °C, Heated Volume 22 and 34lt

| Model No | Max. Temperature (C) | Heated Volume (lt) |

| OVN-VAC-V22C-200 | 200 | 22 |

| OVN-VAC-V34C-200 | 200 | 34 |

Doc No. OVN-VAC-200 February 2015