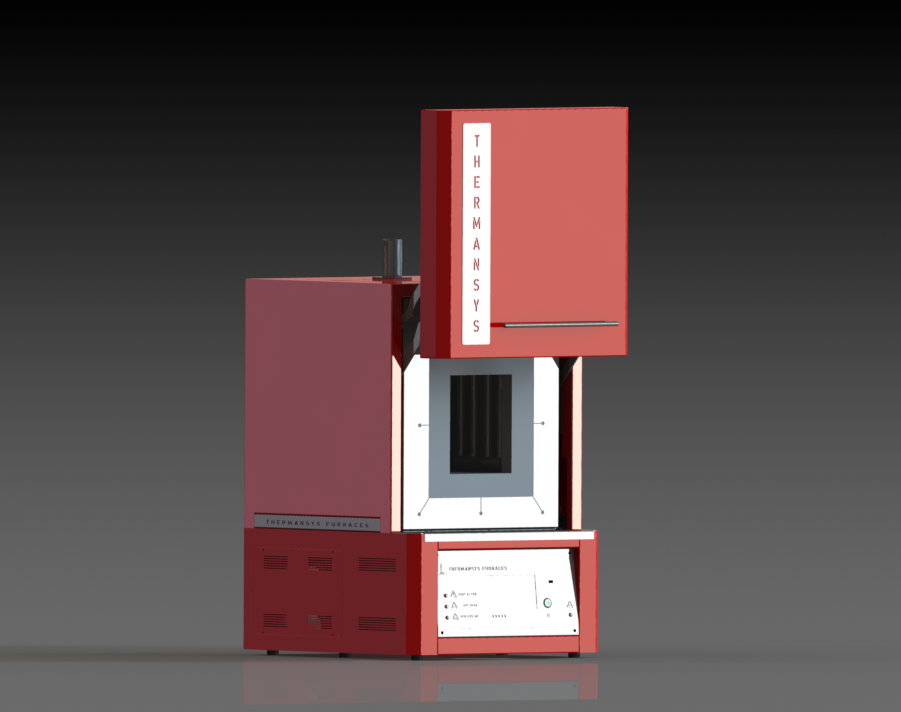

Chamber Furnaces

High Temperature Laboratory Chamber Furnaces up to 1550 ˚C, SiC heaters, 2 to 38 lt

BOX-AS10-1600 and BOX-AS20-1600 chamber furnace families are designed to give repeatable and reliable results in the most aggressive high temperature processes up to 1550 ˚C continuously. Utilizing the unique high density Kanthal SiC resistors these furnaces have superior performance in terms or resistance to oxidation and chemical attack, highly extending the workable life of your investment.

The well recognized absence of Chemical interaction of Silicon Carbite and Zirconia makes this furnace a perfect choice for Dental restorations crowns sintering.

The well recognized absence of Chemical interaction of Silicon Carbite and Zirconia makes this furnace a perfect choice for Dental restorations crowns sintering.

- Maximum Continuous Temperature 1400 or 1550 ˚C.

- Kanthal SiC, exposed type resistors.

- Available models heated volume from 2 to 38 litters.

- Highly resistant in thermal shock.

- Perfect choice for Zirconia sintering.

- Excellent price per performance ratio – Low cost.

- Furnace Chamber Protective Atmosphere (up to two flow control systems).

Key Features

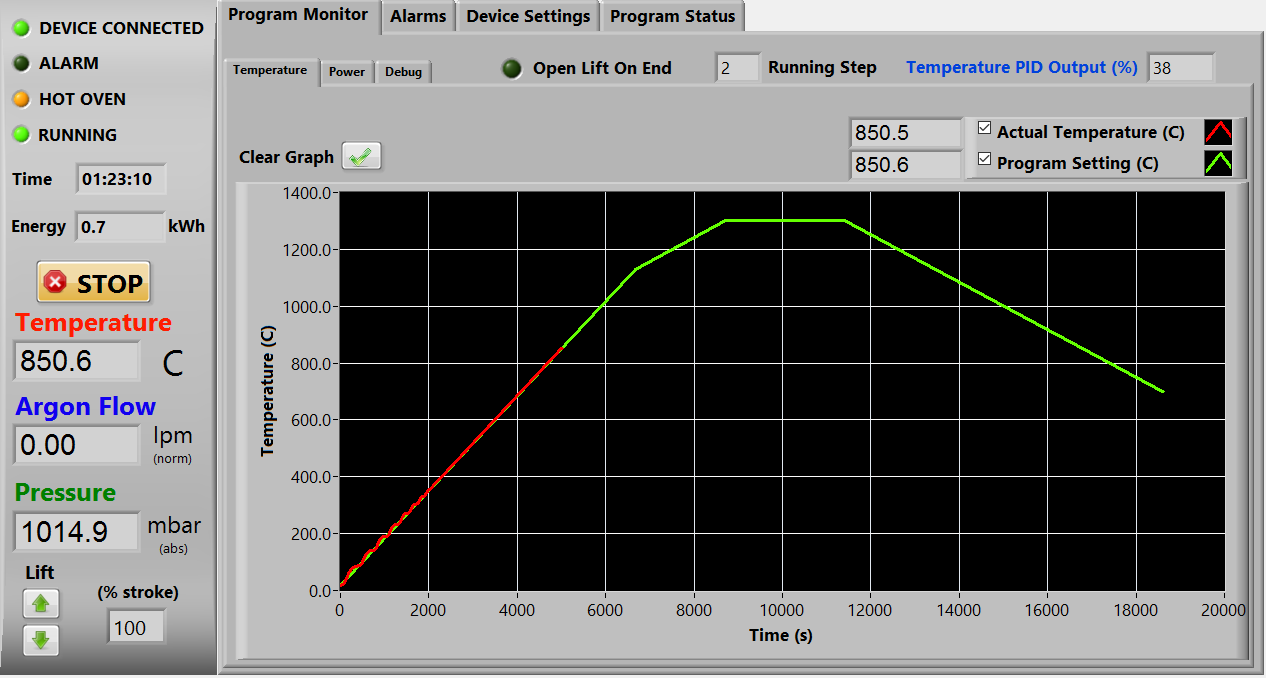

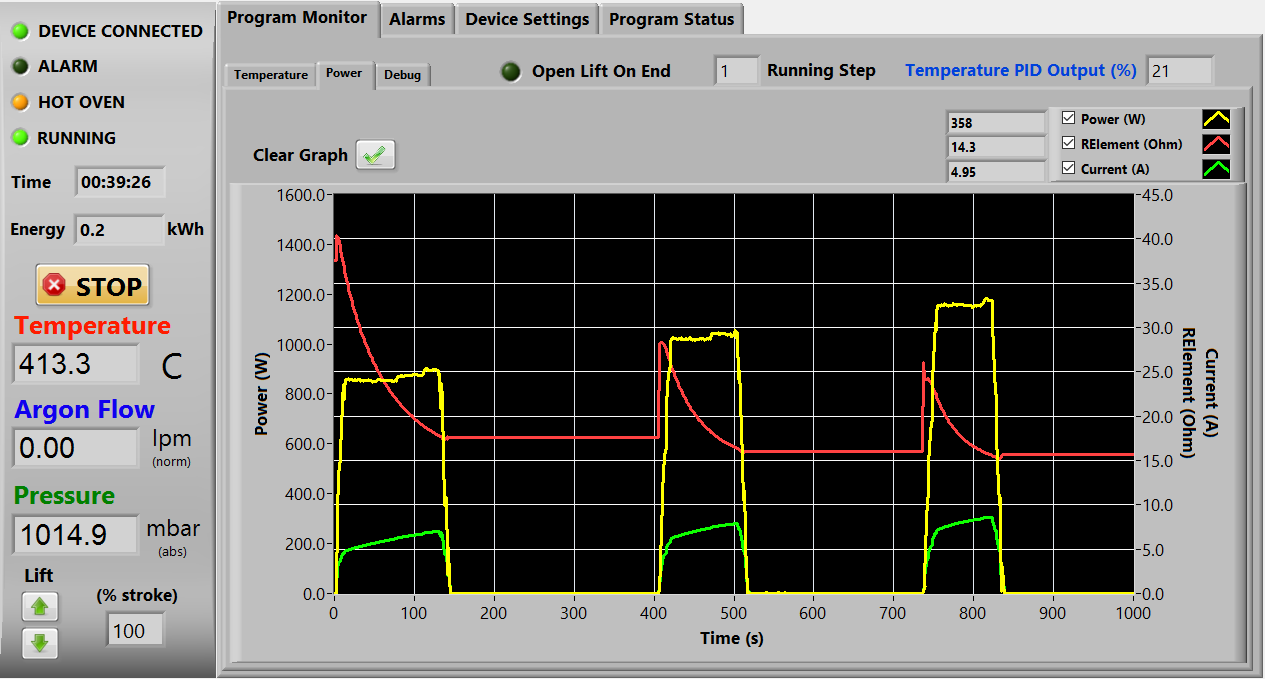

- Control strategy based on Thermansys® PCC (Power Consistent Control) platform insures silent operation and compliance with EMC standards.

- PID Control. Accurate and uniform temperature profiles.

- Modern double wall construction keeps external surfaces temperature low, emphasizing in operator safety. Internal skin is exclusively made from stainless steel to enhance durability.

- Ergonomic design with no protruding edges, bolts or other features combines stainless steel parts with painted finish parts for an improved esthetic result.

- Lift up door keep hot surfaces away from operator.

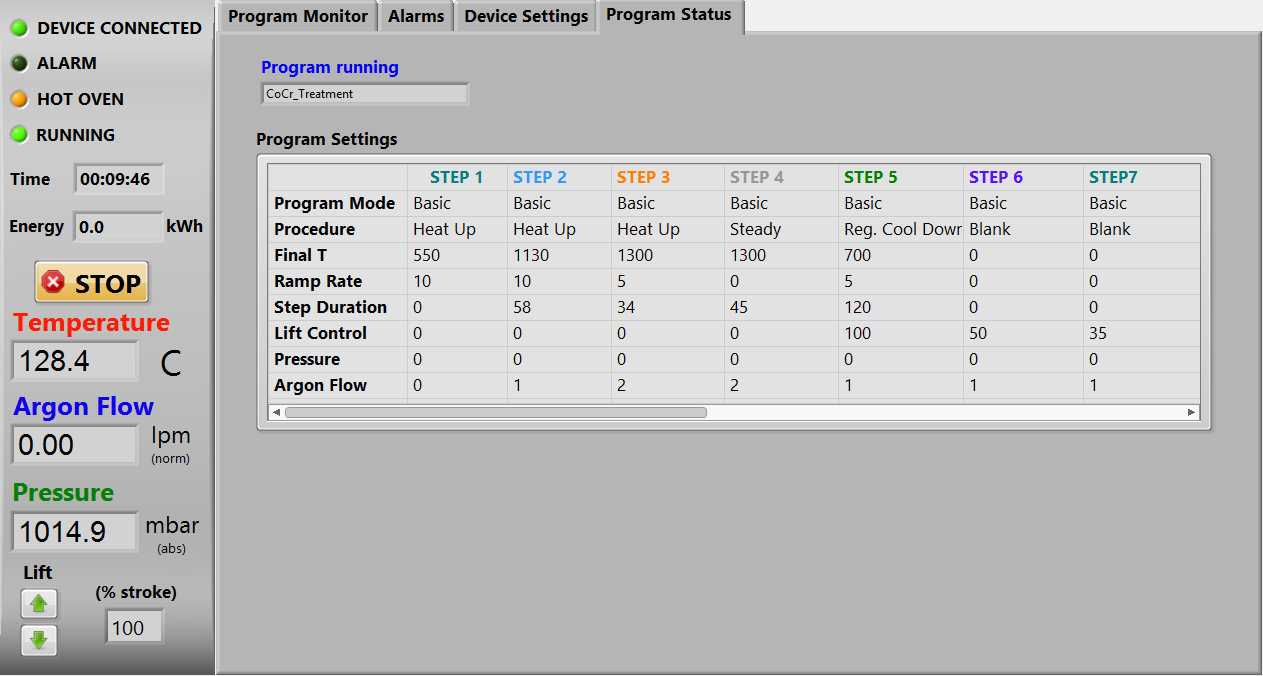

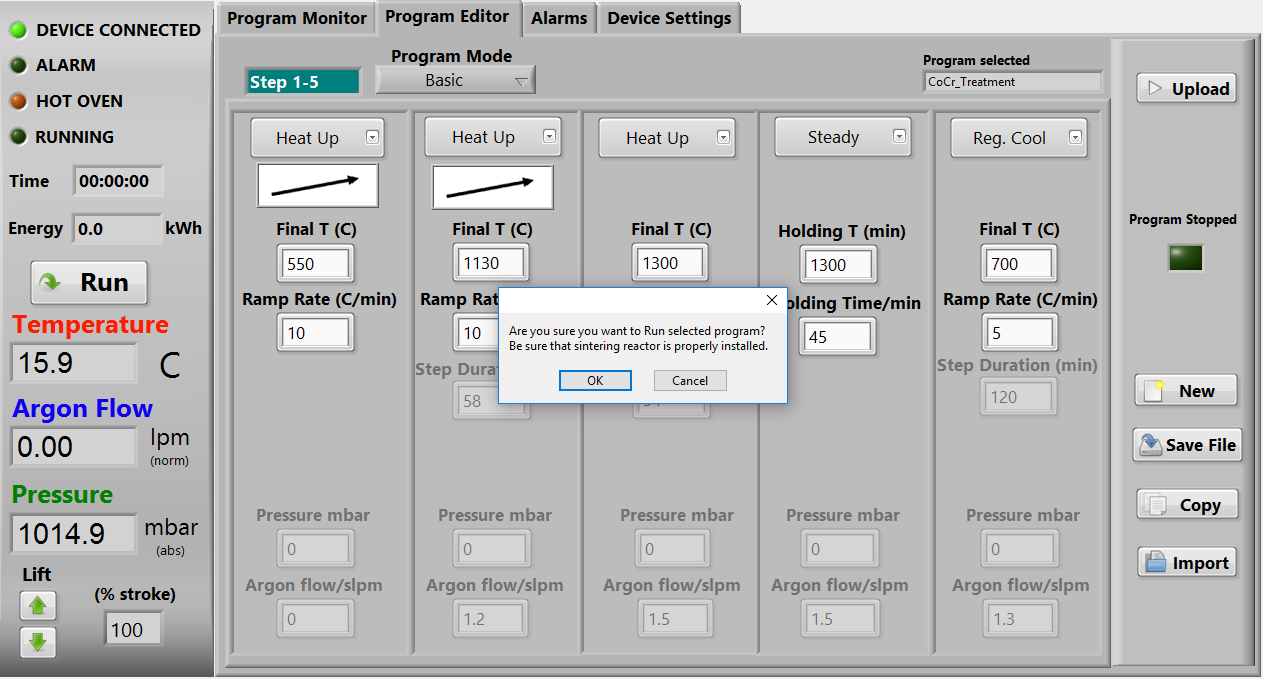

- Touch Screen 7΄΄ Computer embedded running PYROLOGISM software human-machine interface.

- 3 user process thermocouple inputs available (B, E, J, K, N, R, S, T type- software configurable).

- Power and true RMS Current measuring circuits.

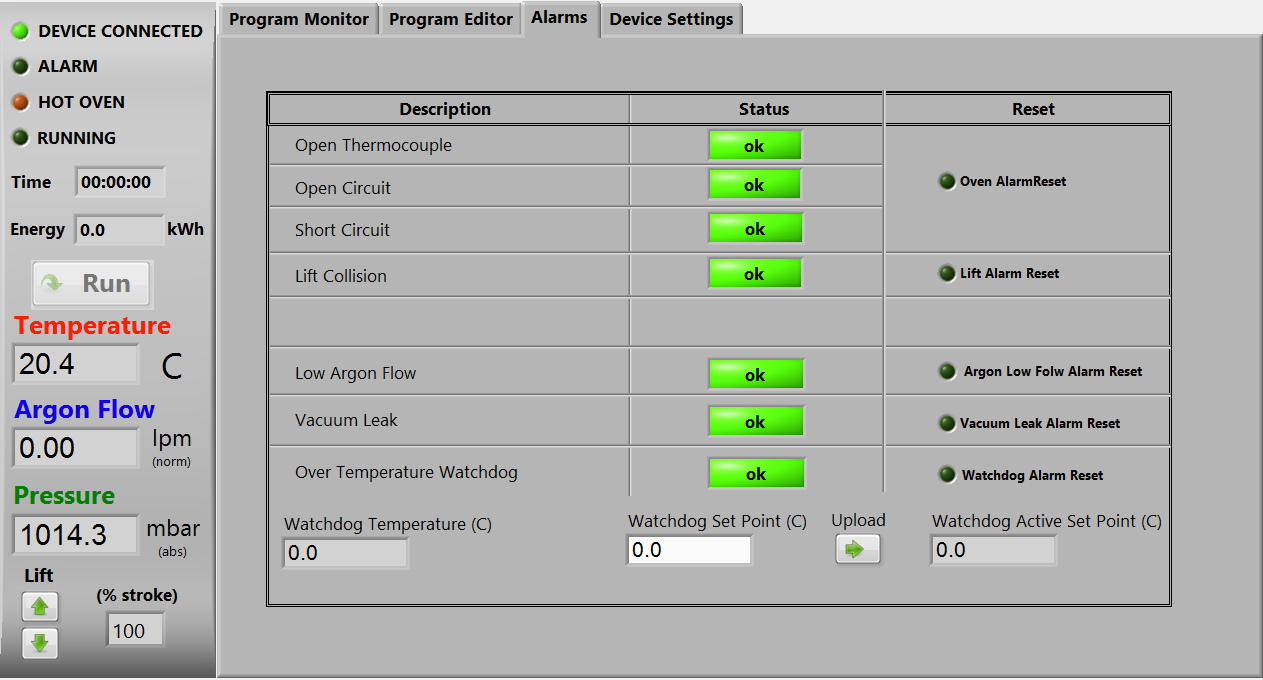

- Heater failure, open control thermocouple detection, door open alarms and interlocks. Alarms and events front panel led array.

- Alarm event output (dry contact 3A/250V AC/DC).

- Stand alone over-temperature limiter (Watchdog) with manual reset in accordance with EN 60519-2 to protect the oven and load. Overrides main controller and cut off heater power if user adjustable high limit is reached.

Specifications

Standard features:

Line 1 gas type calibration: Air

Line 2 gas type calibration: Nitrogen (N2)

Flow range: 0.01-20 std L/min

Accuracy: ±2% of reading for Air, ±3% of reading for N2

Typical Control stability: ± 0.1 std L/min.

Temperature (0-50°C), Pressure (0-15 psig) comp.

Filtration: Not provided, user supplied HEPA grade

CE Certified. Compliant with Low Voltage Directive 2006/95/EC (harmonized referenced standard EN 61010-1: 2001 and EN 61010-2-010:2003) and EMC Directive 2004/108/EC (harmonized referenced standard EN 61326-1:2006).

Produced in GREECE following ISO 9001:2008 quality management system and ISO 14001:2004 environmental management system.

- Maximum temperature 1400 and 1550 °C.

- Operating Power: 240VAC – 50/60Hz.

- Two in depended B type embedded thermocouples for controller and over-temperature limiter. Resolution 0.1 °C

- Temperature control accuracy ±1 ˚C.

- Resistors type: SiC, fully exposed.

- User Thermocouple inputs: 3 chan. - B, E, J, K, N, R, S, T type- software configurable, 24 bit A/D conversion, 0-45°C cold junction compensated, Typical accuracy ±0.2% f.s @ 25 , resolution 0.1 °C.

- Flow controllers:

Line 1 gas type calibration: Air

Line 2 gas type calibration: Nitrogen (N2)

Flow range: 0.01-20 std L/min

Accuracy: ±2% of reading for Air, ±3% of reading for N2

Typical Control stability: ± 0.1 std L/min.

Temperature (0-50°C), Pressure (0-15 psig) comp.

Filtration: Not provided, user supplied HEPA grade

CE Certified. Compliant with Low Voltage Directive 2006/95/EC (harmonized referenced standard EN 61010-1: 2001 and EN 61010-2-010:2003) and EMC Directive 2004/108/EC (harmonized referenced standard EN 61326-1:2006).

Produced in GREECE following ISO 9001:2008 quality management system and ISO 14001:2004 environmental management system.

Models

For detailed ordering and technical information please see our technical brochures:

Maximum Temperature 1550 °C, Heated Volume 3.2 to 8.3lt

Doc No. BOX-AS10-1600 November 2016

Maximum Temperature 1550 °C, Heated Volume 18 to 38lt

Doc No. BOX-AS20-1600 November 2016

Maximum Temperature 1550 °C, Heated Volume 3.2 to 8.3lt

| Model No | Max. Temperature (C) | Heated Volume (lt) |

| BOX-AS10-V3.2-1600 | 1550 | 3.2 |

| BOX-AS10-V3.8-1600 | 1550 | 3.8 |

| BOX-AS10-V5.0-1600 | 1550 | 5.0 |

| BOX-AS10-V6.3-1600 | 1550 | 6.3 |

| BOX-AS10-V8.3-1600 | 1550 | 8.3 |

Doc No. BOX-AS10-1600 November 2016

Maximum Temperature 1550 °C, Heated Volume 18 to 38lt

| Model No | Max. Temperature (C) | Heated Volume (lt) |

| BOX-AS20-V18-1600 | 1550 | 18 |

| BOX-AS20-V26-1600 | 1550 | 26 |

| BOX-AS20-V30-1600 | 1550 | 30 |

| BOX-AS20-V38-1600 | 1550 | 38 |

Doc No. BOX-AS20-1600 November 2016