Tube Furnaces

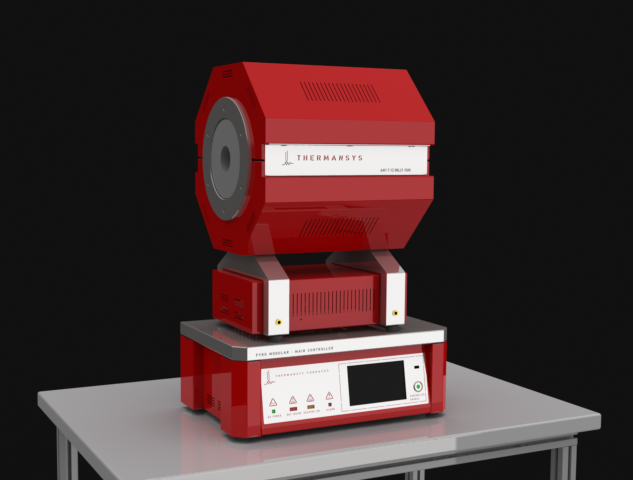

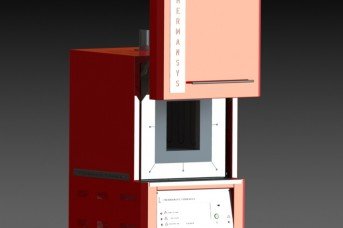

Single/Three Zone High Temp. Tube Furnace, up to 1650˚C-MoSi2 Heaters-Split Tube

- Closed tube models: Universal vertical and horizontal operation.

- Split tube models: Preselected vertical or horizontal operation.

- Hinged split tube or closed tube construction.

- Maximum Continuous Temperature: 1500 ˚C for closed tube, 1550 ˚C for horizontal split tube and 1650˚C for vertical split tube.

- Helical or corrugated type MoSi2 resistors. Excellent radial temperature distribution.

- Extremely high temperature rate. Highly resistant in thermal shock.

- Extremely low density thermal insulation – remarkably high heat up energy savings.

- Three zone models available for extended length uniform axial thermal distribution.

Key Features

- Best available quality KANTHAL® spiral or corrugated shape MoSi2 resistors driven by THERMANSYS® PCC control platform insure furnace long life operation up to 1650 ˚C continuous operation.

- Extremely low mass vacuum formed thermal insulation enables high output available for the load and fast heat up rates while significantly contributes to energy savings under daily thermal cycling.

- Control strategy focusing in high power factor for all workable temperature areas leads to energy savings and insures compliance with EMC (Electro-Magnetic Compatibility) standards.

- Vertical and horizontal mounting flexibility covers different present and future laboratory needs (only closed tube models).

- Very high power density - fast temperature ramping.

- Accurate and uniform temperature profiles.

- Modern double wall construction keeps external surfaces temperature low, emphasizing in operator safety. Internal skin is exclusively made from stainless steel to enhance durability.

- Ergonomic design with no protruding edges, bolts or other features combines stainless steel parts with painted finish parts for an improved esthetic result.

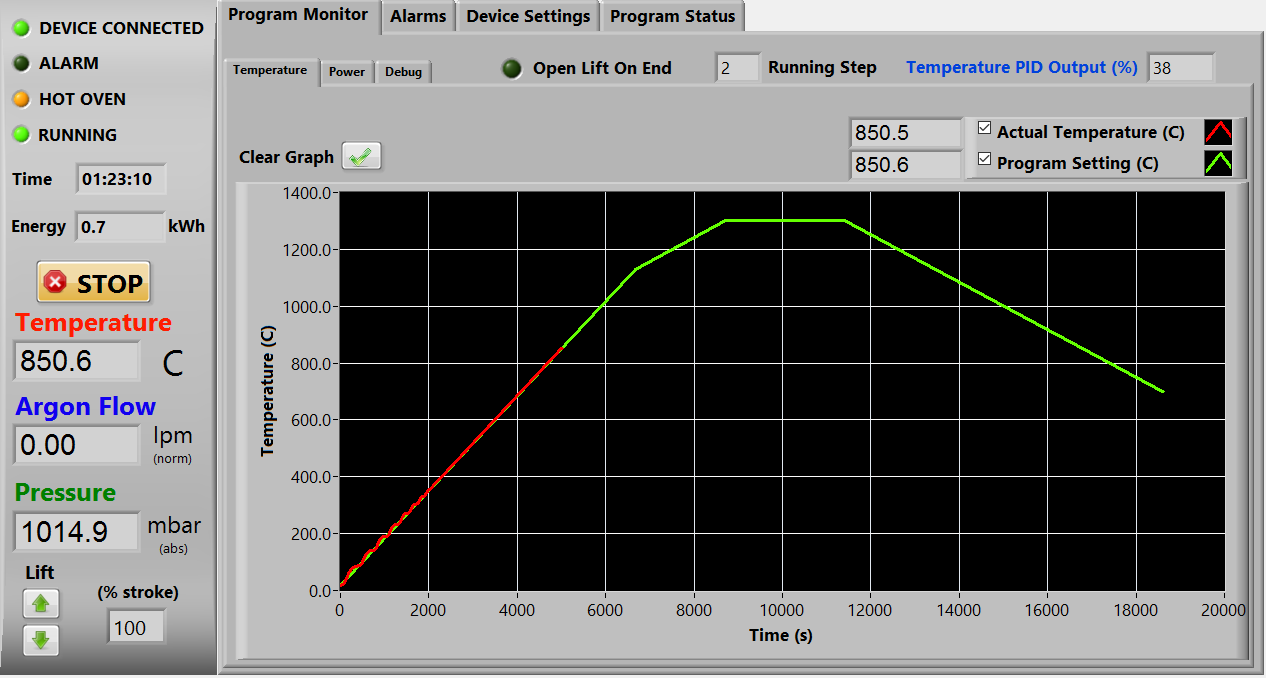

- Temperature PID control.

- USB and Ethernet ports for connection to a PC

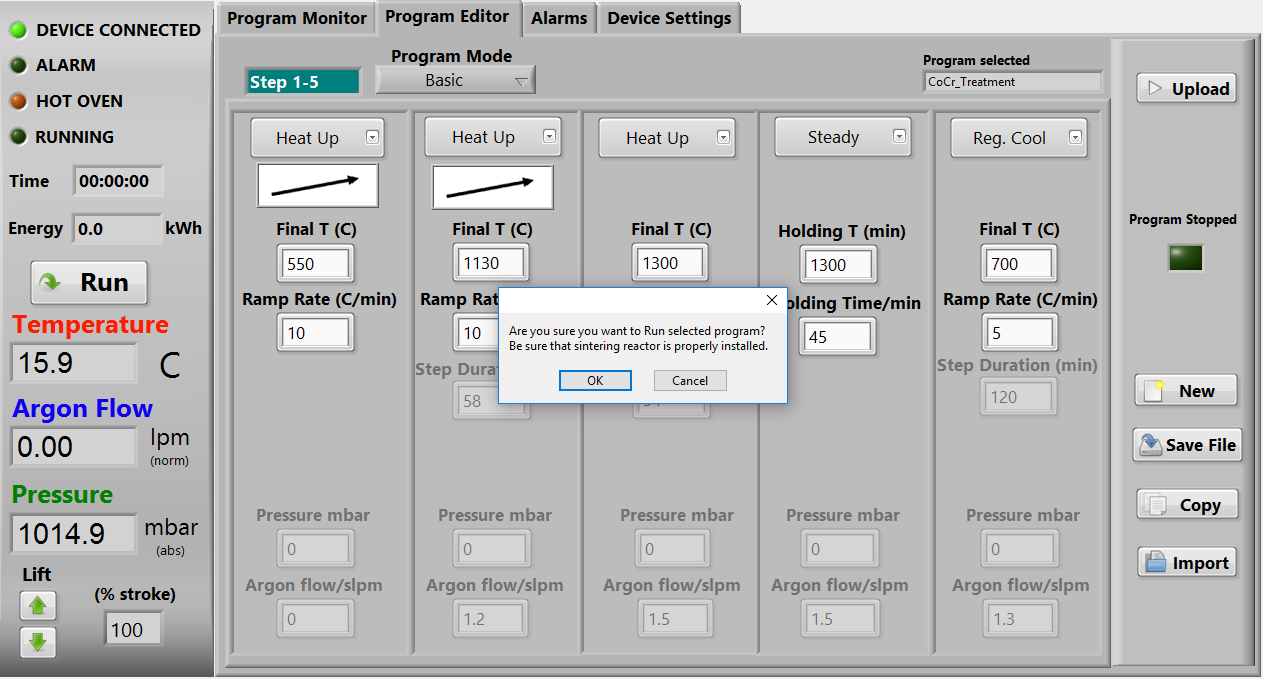

- Touch Screen 7.0΄΄ Computer embedded running PYROLOGISM software human-machine interface.

- 3 user process thermocouple inputs available (B, E, J, K, N, R, S, T type- software configurable).

- Threaded ports facing the heated chamber at the rear panel for Thermocouple probe installation.

- Power and true RMS Current measuring circuits.

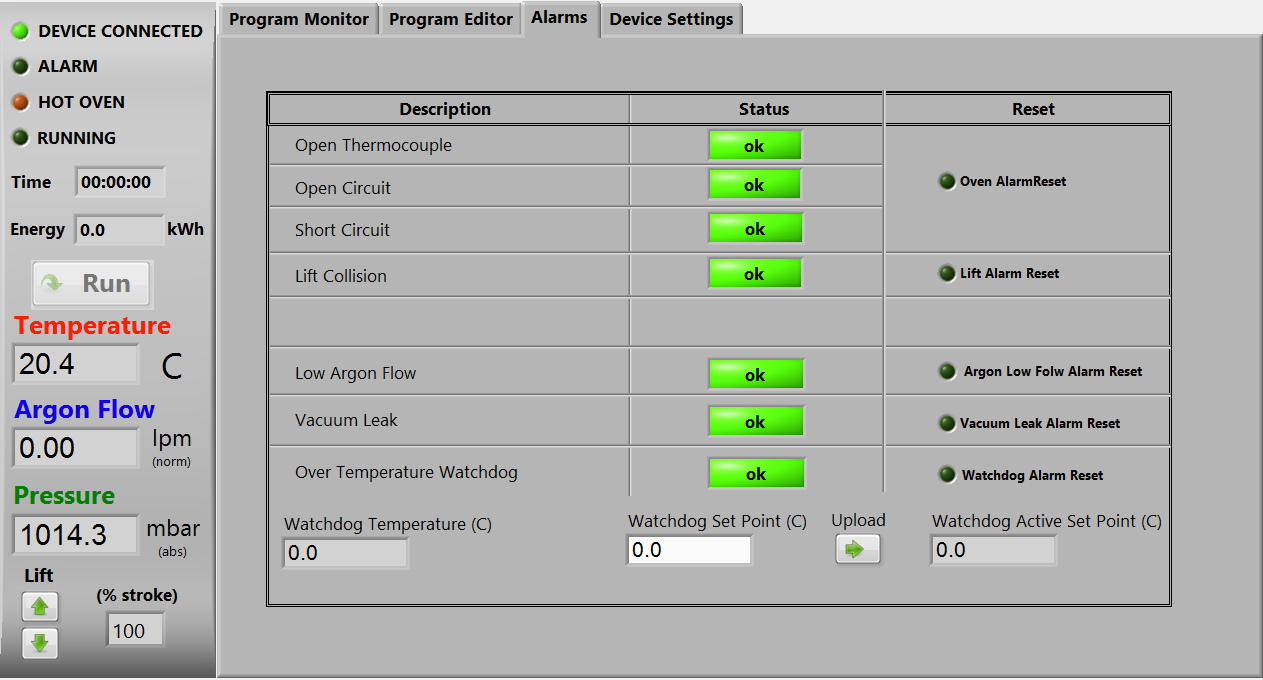

- Heater failure, open control thermocouple detection, door open alarms and interlocks. Alarms and events front panel led array.Alarm event output (dry contact 3A/250V AC/DC).

- Stand alone over-temperature limiter (Watchdog) with manual reset in accordance with EN 60519-2 to protect the oven and load. Overrides main controller and cut off heater power if user adjustable high limit is reached.

Specifications

- Maximum continuous temperature:

- 1650˚C for RCT-AM1-O-1650 Models (Split Tube)

- Operating Power: 208 /240VAC – 50/60Hz.

- B type embedded thermocouples.

- Operation mounting orientation:

Vertical or Horizontal for RCT-AM1-O-1650 Models

- Temperature control accuracy ±1 ˚C.

- Exposed resistors type.

- Single Zone or Three Zones configuration models.

- Each Zone is equipped with two in depended thermocouples for controller and over-temperature limiter feedback.

- Thermocouple inputs:3 chan. - B, E, J, K, N, R, S, T type -software configurable. 24 bit A/D conversion, 0-45°C cold junction compensated, Typical accuracy ±0.2% f.s @ 25 , resolution 0.1 °C

Produced in GREECE following ISO 9001:2008 quality management system and ISO 14001:2004 environmental management system.

Models

Closed Tube, Maximum Temperature 1500C, Single Zone, Universal Operation

| Model No | Max. Temperature (C) | Heated Diam. x Length |

| RCT-AM1-T-1Z-D4L21-1500 | 1500 | 40x210mm |

| RCT-AM1-T-1Z-D4L46-1500 | 1500 | 40x460mm |

| RCT-AM1-T-1Z-D6L21-1500 | 1500 | 60x210mm |

| RCT-AM1-T-1Z-D6L46-1500 | 1500 | 60x460mm |

| RCT-AM1-T-1Z-D9L21-1500 | 1500 | 90x210mm |

| RCT-AM1-T-1Z-D9L46-1500 | 1500 | 90x460mm |

| RCT-AM1-T-1Z-D11L21-1500 | 1500 | 115x210mm |

| RCT-AM1-T-1Z-D11L46-1500 | 1500 | 115x460mm |

Doc No. RCT-AM1-T-1500 November 2012

Closed Tube, Maximum Temperature 1500C, Three Zone, Universal Operation

| Model No | Max. Temperature (C) | Heated Diam. x Length |

| RCT-AM1-T-3Z-D4L71-1500 | 1500 | 40x710mm |

| RCT-AM1-T-3Z-D6L71-1500 | 1500 | 60x710mm |

| RCT-AM1-T-3Z-D9L71-1500 | 1500 | 90x710mm |

| RCT-AM1-T-3Z-D11L71-1500 | 1500 | 115x710mm |

Doc No. RCT-AM1-T-1500 November 2012

Accessories

End Gas Sealing Flanges and Manifolds.

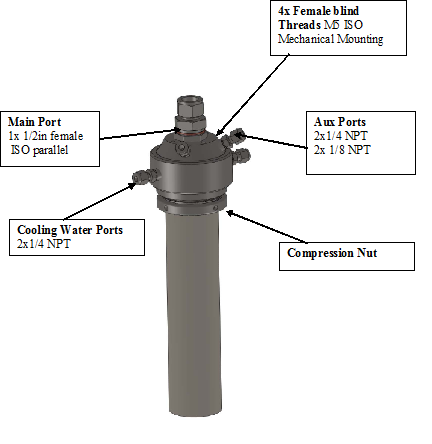

THERMANSYS® is providing work-tube End Gas Sealing Flanges for vacuum or pressure conditions.

These flanges are provided with Main Port either with hydraulic thread port or with Clamp Flange (CF) port for gases inlet/outlet- connection to the tubing network. Cooling fluid recirculation compartment is standard and is removable. Up to four peripheral threads are available serving as ports for instrumentation mounting (e.g thermocouples, pressure sensors).

Versions with Clamp Flange (CF) port design provide quick-open loading port and optionally a quartz sight window.

THERMANSYS® End Gas Sealing Flanges are supplied for work tubes diameters from 1΄΄το 3΄΄. Their design allows use with tubes having diameter tolerance ±10%.

Standard versions material of construction is Stainless Steel ASME 304. Optionally for corrosive applications Stainless Steel ASME 316 is available and Aluminum for a light weight solution (recommended for thin wall Quartz tube reactors).

Reaction Tubes.

Several work tube materials to choose from:

- Dense ceramic Alumina work-tubes for the highest temperature applications.

- Quartz work-tubes for maximum chemical inertia and for aggressive environments to work under vacuum or low pressure conditions up to 1100 ˚C continuously.

- KANTHAL® APMTM/APMT metallic (FeCrAl based) work-tubes to serve under vacuum or pressure up to 1250 ˚C.

Mounting Stands.

Assembled and constructed using BOSCH-REXROTH® structural profile systems these stands provide the ideal solution for vertical furnace stand alone positioning plus reactor and instrumentation mounting. Using the commercially available accessories, tubing and cable routing is easy and professionally accomplished. Stands with electronically actuated furnace move-up and down provide a solution for heating zone moving along the reactor length.

For detailed information and ordering please refer to our Technical Bulletin “Reactor Type Furnaces–Mounting Stands”.

Please contact our sales team for detailed information and ordering on our Tube Furnace Accessories optional equipment.