Tube Furnaces

Modular Tube Furnace, Universal Mounting, up to 1200˚C-FeCrAl Heaters-Split Tube

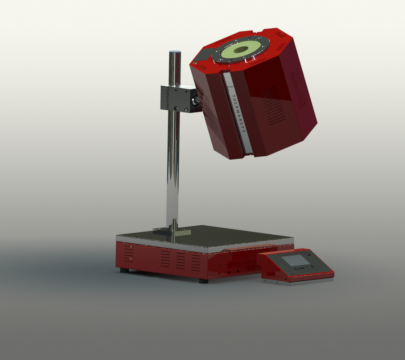

RCT-BW1-1200 furnace family was designed to provide a flexible and functional laboratory solution. This furnace family is suitable for harsh and demanding thermal processes environment up to 1200 ˚C. The furnace can operate in a vertical, horizontal or any intermediate angle position with no restriction.

The hot zone is constructed from high resistance, low porosity ceramic materials. The low density fibrous back insulation allows for rapid heat up and cool down rates while, in conjunction with the double wall design, minimizing energy consumption. The semi-exposed dense structure of metallic resistance (FeCrAl) yielding in extremely uniform thermal distribution profiles. Combined with suitable high heat resistant tube this furnace model is an excellent choice for a number of demanding processes, like combustion-incineration, metal melting under inert or hydrogen atmosphere, fluidized or fixed bed reactions, catalyst testing etc.

The hot zone is constructed from high resistance, low porosity ceramic materials. The low density fibrous back insulation allows for rapid heat up and cool down rates while, in conjunction with the double wall design, minimizing energy consumption. The semi-exposed dense structure of metallic resistance (FeCrAl) yielding in extremely uniform thermal distribution profiles. Combined with suitable high heat resistant tube this furnace model is an excellent choice for a number of demanding processes, like combustion-incineration, metal melting under inert or hydrogen atmosphere, fluidized or fixed bed reactions, catalyst testing etc.

- Hinged split tube or closed tube construction.

- Maximum Continuous Temperature 1200 ˚C.

- FeCrAl resistors. Uniform radial thermal distribution.

- Excellent price per performance ratio. Best seller model for the R&D laboratory.

- Bench top model with stand allowing unlimited positioning flexibility. Available with an automated lifting mechanism.

- Universal, vertical and horizontal operation.

- Optionally three zone construction upon request.

- Comes with integrated controller and remote interface unit.

Key Features

- Control strategy by Thermansys PCC (Power Consistent Control) insures compliance with EMC standards.

- Modern double wall construction keeps external surfaces temperature low, emphasizing in operator safety.

- Ergonomic design with no protruding edges, bolts or other features combines stainless steel parts with painted finish parts for an improved esthetic result.

- Conduits connecting the furnace body with the controller ending in detachable connectors allowing easy movement

- Accurate and uniform temperature profiles.

- KANTHAL® FeCrAl resistors.

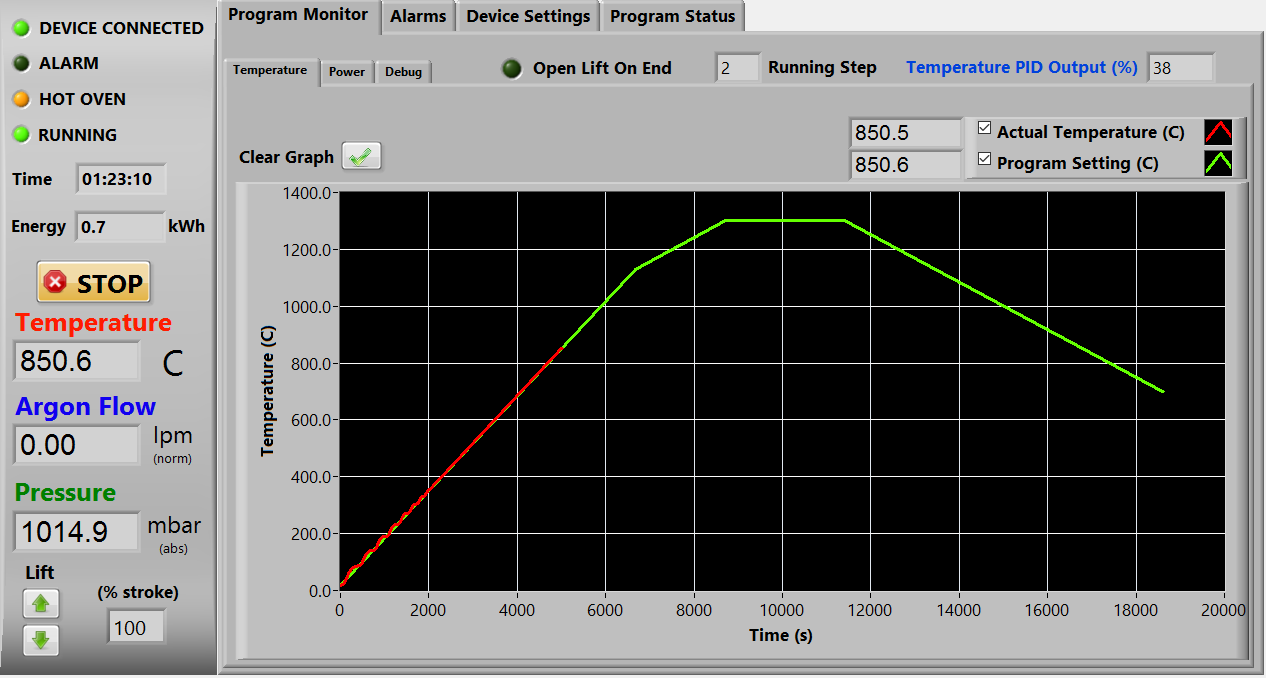

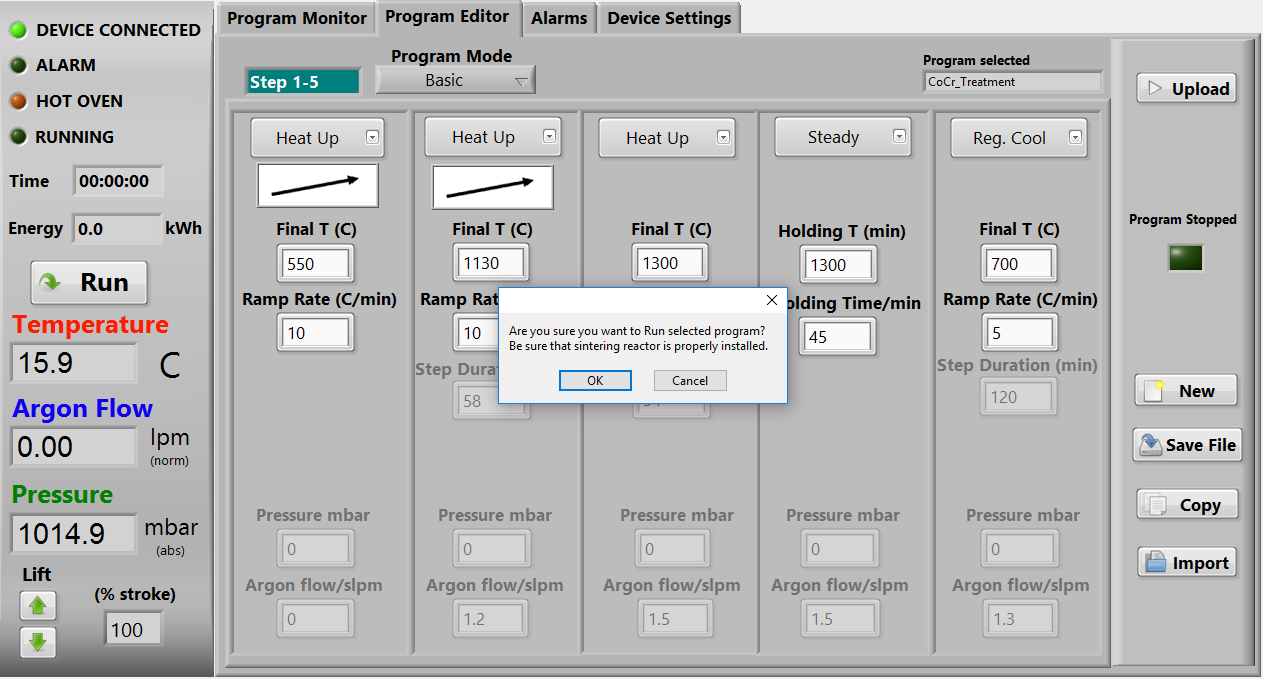

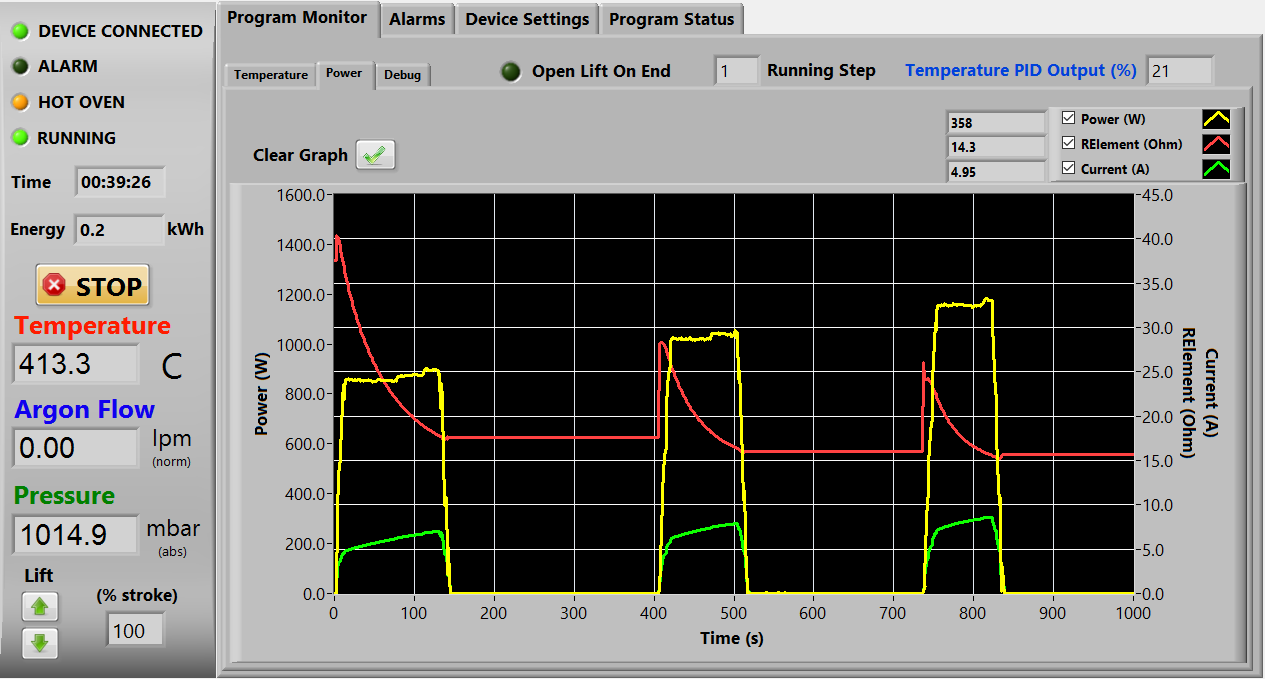

- 4.5΄΄ touch screen computer running the user friendly, PYROLOGISM software.

- 3 channel thermocouple inputs software configurable (B, E, J, K, N, R, S, T type).

- Power and true RMS Current measuring circuits.

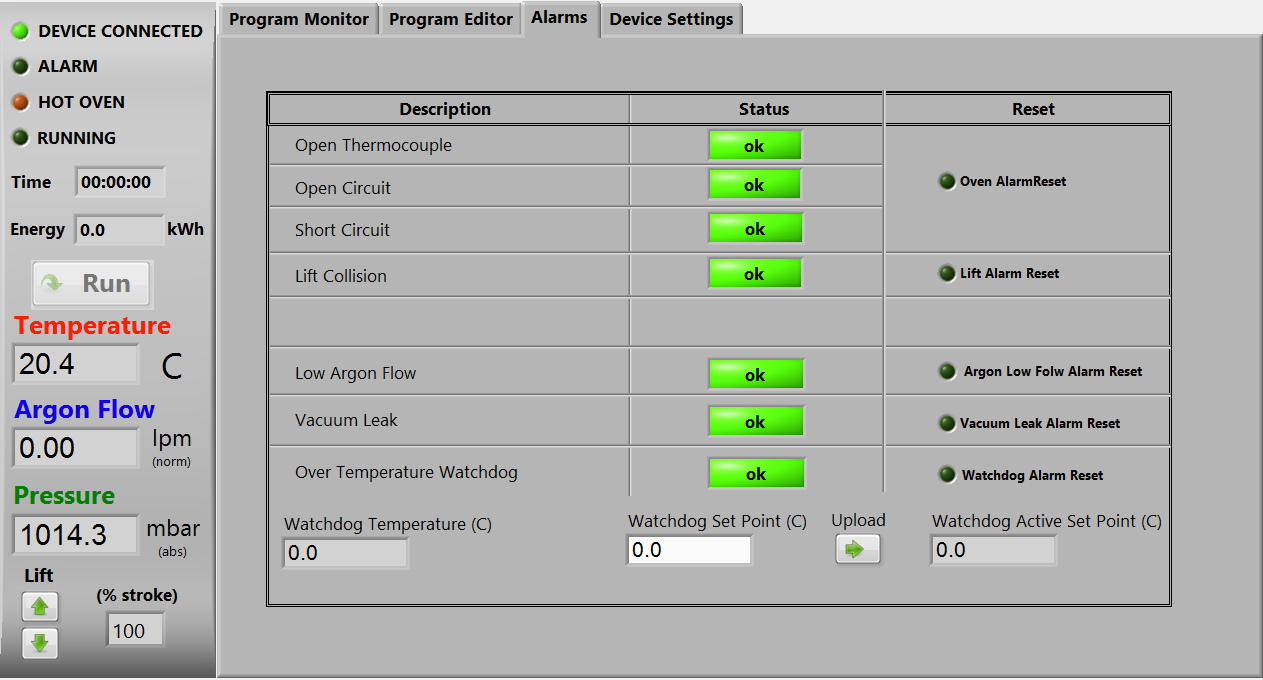

- Heater failure, open control thermocouple detection alarms and interlocks.

- Stand alone over-temperature limiter (Watchdog) with manual reset in accordance with EN 60519-2 to protect the heater and load. Alarm event output (dry contact 3A/250V AC/DC).

Specifications

- Maximum continuous temperature 1200 ˚C.

- Operating Power: 208 /240VAC – 50/60Hz.

- S type embedded thermocouples for main and watchdog controller.

- Temperature control accuracy ±1 ˚C.

- Semi-Exposed resistors type.

- Thermocouple inputs: 3 chan. - B, E, J, K, N, R, S, T type -software configurable 24 bit A/D conversion, 0-45°C cold junction compensated. Typical accuracy ±0.2% f.s @ 25 , resolution 0.1 °C.

Produced in GREECE following ISO 9001:2008 quality management system and ISO 14001:2004 environmental management system.

Models

For detailed ordering and technical information please see our technical brochures:

Closed Tube, Maximum Temperature 1200˚C, Universal Operation

Doc No. RCT-BW1-1200 March 2017

Split Tube, Maximum Temperature 1200°C, Universal Operation

Closed Tube, Maximum Temperature 1200˚C, Universal Operation

| Model No | Max. Temperature (C) | Heated Diam. x Length |

| RCT-BW1-T-D2.6L18-1200 | 1200 | 26x180mm |

| RCT-BW1-T-D2.6L23-1200 | 1200 | 26x230mm |

| RCT-BW1-T-D3.8L18-1200 | 1200 | 38x180mm |

| RCT-BW1-T-D3.8L23-1200 | 1200 | 38x230mm |

| RCT-BW1-T-D5.2L18-1200 | 1200 | 52x180mm |

| RCT-BW1-T-D5.2L23-1200 | 1200 | 52x230mm |

| RCT-BW1-T-D6.4L18-1200 | 1200 | 64x180mm |

| RCT-BW1-T-D6.4L23-1200 | 1200 | 64x230mm |

| RCT-BW1-T-D7.8L23-1200 | 1200 | 78x230mm |

Doc No. RCT-BW1-1200 March 2017

| Model No | Max. Temperature (C) | Heated Diam. x Length |

| RCT-BW1-O-D2.6L18-1200 | 1200 | 26x180mm |

| RCT-BW1-O-D2.6L23-1200 | 1200 | 26x230mm |

| RCT-BW1-O-D3.8L18-1200 | 1200 | 38x180mm |

| RCT-BW1-O-D3.8L23-1200 | 1200 | 38x230mm |

| RCT-BW1-O-D5.2L18-1200 | 1200 | 52x180mm |

| RCT-BW1-O-D5.2L23-1200 | 1200 | 52x230mm |

| RCT-BW1-O-D6.4L18-1200 | 1200 | 64x180mm |

| RCT-BW1-O-D6.4L23-1200 | 1200 | 64x230mm |

| RCT-BW1-O-D7.8L23-1200 | 1200 | 78x230mm |

Doc No. RCT-BW1-1200 March 2017

Accessories

Mounting Stands.

Assembled and constructed using BOSCH-REXROTH® structural profile systems these stands provide the ideal solution for vertical furnace stand alone positioning plus reactor and instrumentation mounting. Using the commercially available accessories, tubing and cable routing is easy and professionally accomplished.

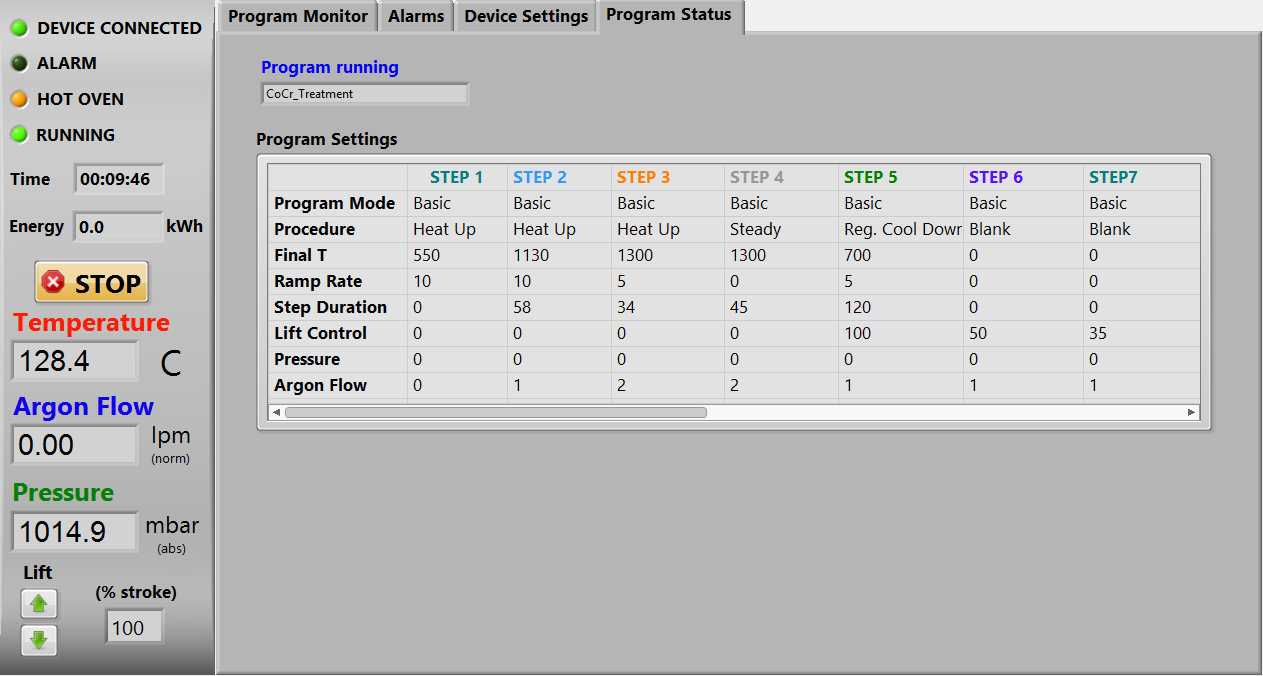

Stand equipped with electronically actuated Lifter allows furnace body up/down linear motion.

Motion is manually actuated through side keyboard and through PYROLOGISM software.

Automated motion programming is possible through PYROLOGISM.

Reaction tubes.

- Dense ceramic Alumina work-tubes for the highest temperature applications.

- Quartz work-tubes for maximum chemical inertia and for aggressive environments to work under vacuum or low pressure conditions up to 1100 ˚C continuously.

- KANTHAL® APMTM/APMT metallic (FeCrAl based) work-tubes to serve under vacuum or pressure up to 1250 ˚C.

End Gas Sealing Flanges and Manifolds.

THERMANSYS® is providing work-tube End Gas Sealing Flanges for vacuum or pressure conditions.

These flanges are provided with Main Port either with hydraulic thread port or with Clamp Flange (CF) port for gases inlet/outlet- connection to the tubing network. Cooling fluid recirculation compartment is standard and is removable. Up to four peripheral threads are available serving as ports for instrumentation mounting (e.g thermocouples, pressure sensors).

Versions with Clamp Flange (CF) port design provide quick-open loading port and optionally a quartz sight window.

THERMANSYS® End Gas Sealing Flanges are supplied for work tubes diameters from 1΄΄ το 3΄΄. Their design allows use with tubes having diameter tolerance ±10%.

Standard versions material of construction is Stainless Steel ASME 304. Optionally for corrosive applications Stainless Steel ASME 316 is available and Aluminum for a light weight solution (recommendedfor thin wall Quartz tube reactors).

Please contact our sales team for detailed information and ordering on our Tube Furnace Accessories optional equipment.